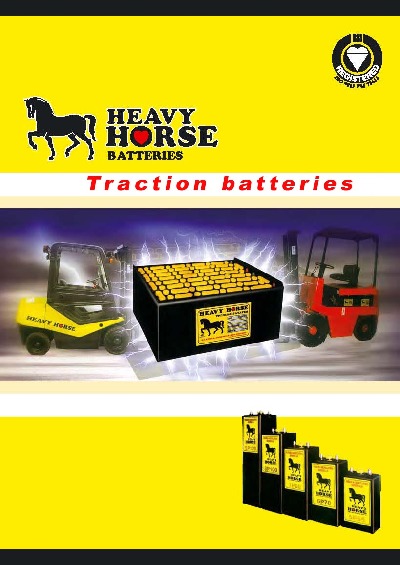

TRACTION BATTERIES

TRACTION BATTERIES

Battery Factory (Serbia) is one of the leaders in production of batteries in Eastern Europe. The company was established in 1952. years. During its history, the factory gained reputation of reliable business partner, with stable and high-quality production. Special attention is paid to quality and ecological safety in the factory. During its operation, since its establishment, the factory has implemented duly modernization of production with wide introduction of authomatization and electronics.

Modern technologies, selected raw materials and strict quality control enable competitive production. The factory produces wide range of starter and traction batteries of various capacity. Batteries produced in factory are exported to the countries of Western and Eastern Europe, Africa and Asia. The company has wide distribution network in Russia and CIS countries. Traction armour battery «HEAVY HORSE» is widely used in electric transport of various types: loading units, electric trucks, storage packaging units and carriages. The main features of «HEAVY HORSE» battery are as follows:

1. Long shelf lite (up to 6 years);

2. Resistance to vibrations;

3. Dry or wet (acid) charging;

4. 1500 cycles of charging-discharging;

5. Elektronic controller;

6. Rigid or elastic compartments;

7. Easy handling;

Energy and exploitation characteristics of «HEAVY HORSE» batteries meet the requirements of GOST, EN, DIN and BS. Production of factory has certificate of ISO 9001, ISO 14001 standard.

Quality of production is one of the main advantages of «HEAVY HORSE» accumulator batteries. Hightechnology materials and advanced technologies are used in production of batteries. Quality control is perfored after each technological operation, which quarantees exceptional reliability of battery. In armour traction batteries, pipe electrodes are filled with active substance in form of suspension, which excludes scattering of active substance. This is an important factor in working conditions in the storages, where loading units and carriages work on rough surfaces and cross the tresholds, etc.

High technology of production of accumulator batteries is supported by modern laboratory, where all existent and accurate testings, measurements and analyses are performed.

Electro-laboratory is equipped for performing tests in order to confirm meeting all global standards, such as ES, DIN, MEK, VAZ, GOST, FORD, FIAT...

Batteries are also featured by increased resistance to corrosion of lead electodes for removal of current. There are several ways of battery charging: for operation in cold, moderate or tropical climate. Traction armour batteries «HEAVY HORSE» are mostly used in loading units of Bulgarian production: Balcancar, Dimex and others, - as they fully match with their AKB capacity of 165 to 560 A/h. The factory produces on request the batteries of various size with capacity of 1200 A/h. When placing order, it is necessary to give the followin information:

Batteries are also featured by increased resistance to corrosion of lead electodes for removal of current. There are several ways of battery charging: for operation in cold, moderate or tropical climate. Traction armour batteries «HEAVY HORSE» are mostly used in loading units of Bulgarian production: Balcancar, Dimex and others, - as they fully match with their AKB capacity of 165 to 560 A/h. The factory produces on request the batteries of various size with capacity of 1200 A/h. When placing order, it is necessary to give the followin information:

1. Battery voltage

2. Capacity of battery at five-hour discharging

3. Battery size

4. Name and type of electric hoisting device – transport unit

5. Special requirements

Traction batteries, produced on request in the factory can be used in transport units of local, European (Linde, Rocla, Still, Jungheinrich) and Asian (Toyota, Nissan, Mitsubishi, Daewoo, Komatsu) production.

TECHNICAL CHARACTERISTICS OF TRACTION ELEMENATS

Traction Batteries1eng.pdf |

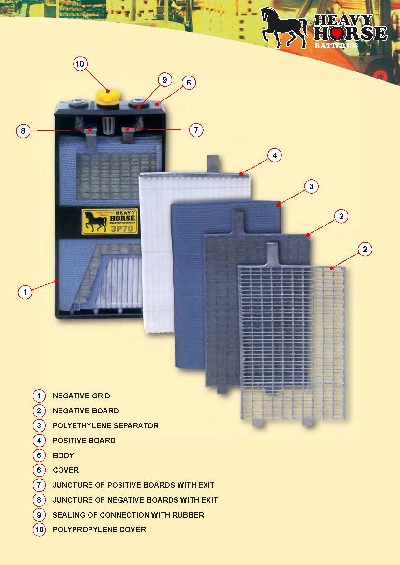

BATTERIES CONSTRUCTION

Battery consists of accumulators, interconnected with compartments, placed in special metal plastic coated case, equipped with openings on the walls for traction and drainage openings on the bottom. Accumulator battery consists of blocks of positive electrodes in the form of pipe lined boards (PzS) and blocks of negative electrodes in the form of grid boards. Separators are positions between the electrodes. Microporous separation material is used for separators.

Electrodes of both polarities are connected by little bridges made of lead alloy and antimony with current exits. Special construction of pole exits ensures airtightness of electroyltes in accumulator batteries. The body of accumulator battery and its cover are inter-connected in airtight way and made of polypropylene, shock and heat resistant. Airtight polypropylene cover with the tops which can be opened for topping up the accumulator battery with electrolyte, measuing density and temperature of electrolyte is placed on the cover. The cover enables free exit of gases and does not allow spilling of electrolyte from accumulator battery during exploitation, it protects against intrusion of foreign particles. Punched protection plastic grid is placed into every accumulator battery from the top on electrode block in order to give protection against incidental intrusion of foreign particles.