Black Horse 22.05.pdf |

Tesla Premium Energy 22.05..pdf |

Asian Horse 22.05..pdf |

Battery Factory from Serbia, has been in the lead-acid starter battery market since 1952, having transformed from a small workshop for assembling and servicing of 6V and 12V batteries. Since then, the firm has experienced steady progress though it was not until 1974 than it came to a turning point and took a direction of dynamic development. It was then when the US-based GLOBE UNION´s licence was bought, boosting improvement of technology and equipment, due to the company`s expertise and experience. In 2004 a new generation of batteries based on calcium technology was launched on the market, this required modernization of the production process. Leading manufacturers` machines and equipment such as WIRTZ, TEKMAX, TIEGEL, MAC, SOVEMA, TBS etc. have been installed meeting the requirements of EN 50342.

Battery Factory from Serbia, has been in the lead-acid starter battery market since 1952, having transformed from a small workshop for assembling and servicing of 6V and 12V batteries. Since then, the firm has experienced steady progress though it was not until 1974 than it came to a turning point and took a direction of dynamic development. It was then when the US-based GLOBE UNION´s licence was bought, boosting improvement of technology and equipment, due to the company`s expertise and experience. In 2004 a new generation of batteries based on calcium technology was launched on the market, this required modernization of the production process. Leading manufacturers` machines and equipment such as WIRTZ, TEKMAX, TIEGEL, MAC, SOVEMA, TBS etc. have been installed meeting the requirements of EN 50342.

BLACK HORSE is now a familiar brand name in the markets of Europe, Africa and Asia.

The Factory can turn out 1,000,000 batteries per annum (36 Ah through 235 Ah), ranking it among prominent battery manufacturers in this part of Europe.

The said achievements serve as basis for further development and expansion.

PRODUCTION

The Battery has invested into new continuous casting technology, which in terms of product quality, proved to be superior over other casting systems. It is also in line with the latest developments of the battery industry.

Via continuous casting of the negative calcium grid and continuous plate pasting manufacture of the hybrid starting battery has commenced. The said technology results in lighter, stronger, high-quality batteries and the current capacities installed is 1,500,000 units per annum.

The plate design of the continuous-cast full-frame grid adds firmness to the thin carrier, resulting in enhanced vibration-resistance during use. The casting technology enables manufacture of such grid structure, which is exceptionally resistant to corrosion at high temperatures of up to +75C.

Lead powder, a key component in the production of lead-acid batteries, is manufactured with equipment from the Italian mill-maker Sovema.

Wirtz pasting machine is the most modern of its in the world and used only by the most prominent battery manufacturer. This sophisticated machine performs complete pasting of both sides of grids thus enhancing battery performance

The new assembly line has been chosen to ensure high quality and productivity.

High quality, thin, micro-porous, polyethylene, pocket separators eliminate all shortcut possibilities during use as well as reducing electric resistance and enhancing starting at low temperatures. TEXMAX machines perform enveloping of plates and stacking cells.

TBC cast on strap machine produces an excellent combination of quality, flexibility and speed.

Starting ability as well as resistance of battery to vibration depends on the quality of the intercellular weld. Therefore, the factory had the renowned American Machine maker, Tiegel`s machine installed.

In he final stage of assembly, the battery lid is thermally connected to the container. Contact surfaces are heated and bound by pressing against each other. Another unit of the same machine tests whether cells and the lid-container are properly sealed.

Aiming at the highest possible final product quality, every single battery is tested for voltage without load and under extreme load. The unit for final control testing is computer-controlled and every single battery has to meet the values set by the software resulting in standard quality of all the batteries produced.

QUALITY

The ISO 9001-2000 certificate of quality was received from BSI Management Systems certifying the level of quality of batteries manufactured by Battery Factory Serbia.

Company starter batteries with brand name BLACK HORSE have been assigned European Type Number (ETN) which means that these batteries have been made in accordance with European Norm EN 50342.

LABORATORY

A modern laboratory, equipped for the most accurate testing, measurement and analysis supports the high manufacturing technology.

Testing as per all renowned international standards, such as EN, DIN, IEC, VAZ, FORD, FIAT etc. is computer aided, ensuring reliability and accuracy.

Apart from standard testing, the laboratory conduct special analysis aiming at improvement and introduction of new solutions into the production of lead acid batteries.

COLD CRANKING PERFORMANCE (AMPERE)

The Cold Cranking Performance (CCA) measures the starting performance of the battery. In simple terms, the higher the CCA, the easier it will be to start the vehicle.This test is starting test according to the EN 50342 standard. Other manufacturers use different standard tests such as DIN, JIS, and SAE etc.The test specifies that the battery at the temperature of -18° will deliver a current equal to the Cold Cranking Amps for 10 seconds with the voltage staying above 7.5 volts. Battery performance drops off quickly with the temperature, so this test is a good check of a battery`s starting ability.

The Cold Cranking Performance (CCA) measures the starting performance of the battery. In simple terms, the higher the CCA, the easier it will be to start the vehicle.This test is starting test according to the EN 50342 standard. Other manufacturers use different standard tests such as DIN, JIS, and SAE etc.The test specifies that the battery at the temperature of -18° will deliver a current equal to the Cold Cranking Amps for 10 seconds with the voltage staying above 7.5 volts. Battery performance drops off quickly with the temperature, so this test is a good check of a battery`s starting ability.

AMPER-HOUR CAPACITY AT 20 HOUR RATE (Ah)

The Ampere-Hour capacity measures the total amount of electricity stored in a battery.An Ampere-Hour represents the amount of electricity when a current of 1 Ampere passes for 1 hour.The Ampere-Hour Capacity varies with the rate at witch the battery is discharged; the slower the discharge, the greater the amount of electricity that battery will deliver.The Ampere-Hour Capacity is the amount of electricity that a battery will deliver during 20 hours of operation, before the voltage drops below 10.5 V. For example, a 60 Ah battery will deliver a current of 3A for 20 hours.

The Ampere-Hour capacity measures the total amount of electricity stored in a battery.An Ampere-Hour represents the amount of electricity when a current of 1 Ampere passes for 1 hour.The Ampere-Hour Capacity varies with the rate at witch the battery is discharged; the slower the discharge, the greater the amount of electricity that battery will deliver.The Ampere-Hour Capacity is the amount of electricity that a battery will deliver during 20 hours of operation, before the voltage drops below 10.5 V. For example, a 60 Ah battery will deliver a current of 3A for 20 hours.

RESERVE CAPACITY (MINUTES)

The Reserve Capacity is the amount of time in minutes that a battery at 25°C can deliver a current of 25 Amps until the voltage drops to 10.5 V.25 Amps represents a typical electrical load on a car under normal running condition, so the Reserve Capacity gives an indication of the time that a vehicle with a normal electrical load will run a broken alternator or fan-belt.Obviously, the more electrical accessories you turn off, the further you an drive the car.

The Reserve Capacity is the amount of time in minutes that a battery at 25°C can deliver a current of 25 Amps until the voltage drops to 10.5 V.25 Amps represents a typical electrical load on a car under normal running condition, so the Reserve Capacity gives an indication of the time that a vehicle with a normal electrical load will run a broken alternator or fan-belt.Obviously, the more electrical accessories you turn off, the further you an drive the car.

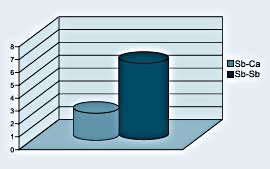

WATER CONSUMPTION

Ca-Sb batteries, compared to Sb-Sb batteries, have less water loss, which ranks them among `maintenance free` batteries.

Ca-Sb batteries, compared to Sb-Sb batteries, have less water loss, which ranks them among `maintenance free` batteries.

Batteries manufactured 30 years ago were wasting water too quickly making it necessary for drivers to check water level in battery once a week. However, modern, maintenance free batteries do not need fill-up with water during their lifetime, under normal operating conditions. During the same period battery life has doubled.Earlier, 10% of antimony was added to lead alloy to improve the strength of lead in grids. However, it had a negative effect since a certain quantity of antimony dissolved in the acid, and resulted in the battery losing water.Due to improved technology, the 10% level of antimony could be reduced to 1.5% and batteries demanded maintenance once a yearonly. The present state of art in battery manufacture makes it possible that only 0.1% calcium is used in the lead alloy to create the same strength effect. Thus there is less contamination of the acid and much reduced water loss. These are maintenance free batteries,where no fill up is necessary during their lifetime.